Mitra Hazard adalah distributor produk electrical equipment explosion proof dari beberapa produsen ternama dari negara-negara Eropa dan Amerika, diantaranya Emerson-Appleton, ATEX Delvalle, dan TEPEx. Seluruh produk telah mengantongi izin dan sertifikat berstandar explosion proof dari ATEx, IECEx, CE, dan sebagainya. Tersedia produk berstandar explosion proof seperti lampu explosion proof (tube light, flood light, high bay, dan sebagainya) box empty enclosure, box control station, junction box, terminal box, dan produk cable gland dan pipe fitting, mulai dari non armoured, armoured. Mitra Hazard juga mendukung pengiriman ke seluruh Indonesia, terutama wilayah Jakarta, Bogor, Depok, Tangerang, Bekasi, Cilegon, Serang, Rangkas Bitung, Karawang, Cikarang.

Appleton LED Tube Light Explosion Proof ATXTM FELED Series Nonmetallic

Applications

- For use in locations where:

- Hazardous areas are designated as Zone 1 and 2 – 21 and 22 — A high degree of corrosion resistance is required

- Protection against dirt, water and moisture is necessary Typical applications include:

- Oil refineries

- Petrochemical facilities

- Food processing plants

- Waste and water treatment plants

- Underground tunnels

- General manufacturing facilities

Features

- Available in 5000K or 4000K Color Temperatures.

- Meets photobiological requirement for Risk Group 0 (RG0).

- Easy to retrofit in same mounting footprint as Appleton’s FE series nonmetallic fluorescent luminaires.

- Full range of lumen outputs, with light distribution equivalent to Appleton’s FE series fluorescent luminaires.

- Corrosion-resistant fiberglass reinforced polyester body and hinged polycarbonate lens.

- High impact resistance housing (20 Joules – IK10) from -30 °C to +55 °C (-22 °F to +131 °F) ambient temperature and wind profile for use in extreme offshore and onshore environments.

- 60,000+ hour LED life for years of maintenance free operation.

- Lightweight design, hinged cover with captive screws, and terminal block wiring for easy installation and maintenance.

- Contemporary, low profile design suitable for tight spaces.

- Standard screw-type terminal block can accept 1.5 to 6 mm2 wire.

- Field replaceable LED driver.

- Industry-leading thermal management for safe, reliable operation over wide temperature range.

- Universal, high efficiency, drivers cover voltage requirements for 120-277 Vac, 170-300 Vdc, 50/60 Hz +/- 10%.

- High power factor electronic driver (>0.95).

- Standard 6KV surge suppression.

- M20 plug or M25 plug provided.

- Latch assembly and elastomer gasket seals against water and dust ingress, IP66.

- Easily accessed for maintenance using Allen key or straight blade screwdriver.

- Central opening with unique patented release system to prevent damage.

- Can be horizontally or vertically mounted.

- Available in 3 hour emergency version, including built-in monthly self- test. Test results through multi-colored LED.

- Positive safety switch disconnects power to LED’s and driver to allow maintenance in hazardous locations (emergency version).

- Ex e battery with plug-in connector.

Category: Uncategorized

Brand

Brand

Appleton

Reviews (0)

Be the first to review “Appleton LED Tube Light Explosion Proof ATXTM FELED Series Nonmetallic” Cancel reply

Related products

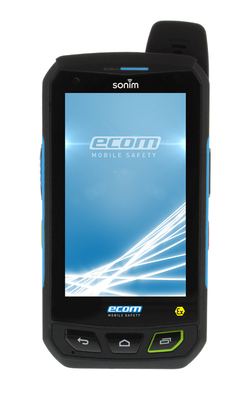

ECOM Intrinsically safe smartphone: Smart-Ex® 01 for Zone 1 / Division 1

Worker safety with Smart-Ex® 01

An ultra-rugged, unlocked, LTE / WiFi / Android™ smartphone, the Smart-Ex® 01 comes with unrivalled features:

- Such as a touch screen that can be viewed in direct sunlight and easily used with dirty or wet work gloves.

- An extremely loud speaker, noise cancellation, a powerful battery, water and drop resistance and an optional 3-Year Service Level Agreement are just some features of the Smart-Ex® 01 that provide peace of mind to enterprises and workers alike.

- Access to productivity applications and worker safety as well as a full suite of industrial-grade accessories completes the solution.

- Unlocked and SIM free – allowing connection to any network worldwide

- 9th generation of I.S. mobile phones (reliability track record)

- Quality control conducted in Germany, based on 30 years experience in the Ex-market

ECOM Pad-Ex® 01 P8 D2 – Windows Tablet (Division 2)

Pad-Ex® 01 P8 D2 redefines what a mobile Full Win tablet PC shall be:

While being given its level of ruggedness, Pad-Ex® 01 P8 D2 meets all the environmental requirements and supports the 8th generation Intel® Core™ i5 processor. It also provides battery life up to 7 hours and Windows® 10 Pro support.

Combining robust features and a large screen size, superior performance is ideal for field operatives of all sectors to complement or even substitute Desktop PC, laptop or wall mounted display.

HOFFMAN Hazardous Location Breather Drains

Hazardous Location Breather Drains prevent moisture build-up within hazardous approved enclosures while maintaining enclosure UL Type rating. Drains are to be used when an enclosure is subject to fluctuations in temperature which can lead to the formation of condensation and a subsequent moisture build-up. These drains allow air within an enclosure to breathe with the surrounding atmosphere, preventing condensation and any potential damage to electrical equipment.

ECOM New Intrinsically Safe 4G/LTE Ex-Handy 10 DZ2 for Zone 2/22 & DIV 2

ECOM Pad-Ex® 01 P8 DZ2 – Windows Tablet (Zone 2/22 & Division 2)

Pad-Ex® 01 P8 DZ2 redefines what a mobile Full Win tablet PC shall be:

While being given its level of ruggedness, Pad-Ex® 01 P8 DZ2 meets all the environmental requirements and supports the 8th generation Intel® Core™ i5 processor. It also provides battery life up to 7 hours and Windows® 10 Pro support.

Combining robust features and a large screen size, superior performance is ideal for field operatives of all sectors to complement or even substitute Desktop PC, laptop or wall mounted display.

ECOM Intrinsically safe smartphone: The new Smart-Ex® 02 for Zone 1/21 & Division 1

Variable product example

$5.00 – $15.00

Reviews

There are no reviews yet.